- 01 Environment

- 02 About Us

- 03 Products

- 04 SF6

- 05 Applications

- 06 Academy

Piping Systems

Piping Systems

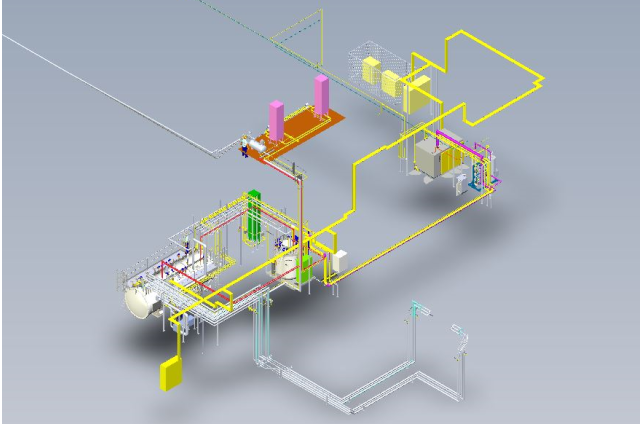

On the basis of the experience gained in sulphur hexafluoride gas distribution systems, Synecom has also extended its interest in the field of elementary stainless steel piping, but also in more complex cryogenic piping systems with vacuum chambers, for the management and transport of liquid and gaseous fluids even at very low temperatures, which connect the various equipment in a plant.

Our company supplies turnkey plants, taking care of the preliminary engineering study, the elaboration of 2D isometric drawings for the construction and layout of the plant, 3D modelling for the overall view of the plant using the most advanced software, stress analysis using the finite element method extended also to the support components, up to the factory construction of the elements and the installation of the plant at the customers' sites, using the derived P&ID schemes.

Welded joints, both in the factory and on site, are carried out by ASME and EN certified welders. The supply chain that Synecom offers in this sector concludes with consistency checks and non-destructive tests (NDT) of all mechanical and welded couplings.

Radiographs in the factory and on site are conducted by the company's trusted laboratories, while all other leakage tests using gas leak detector (helium, nitrogen, gas mixtures) are carried out directly by Synecom personnel, appropriately certified for 2nd and 3rd level according to ISO 9712-2012 and SNT TC 1A.

Synecom collaborates with research institutes and large industries in the sector, including the production, installation and TND of the cryogenic plant for the MITICA experiment at the PRIMA site of the CNR in Padua. For the same experiment, Synecom has also produced, installed and tested the SF6 insulating gas distribution plant for the NBTF line.